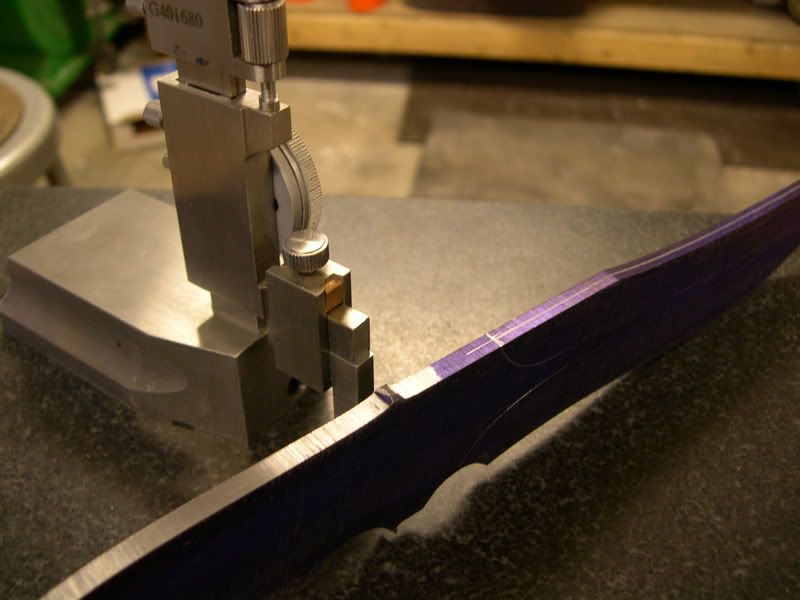

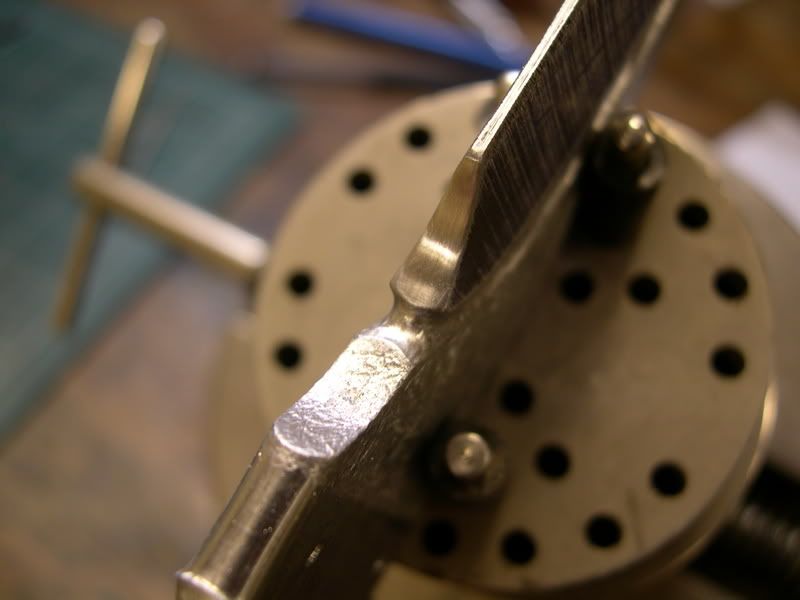

Top side of the fuller,

Choil area,

Side view of the completed texturing.. After heat treat I'll bring the grinds all the way to the fuller.

Finally ready for Heat treat,

I knew I should have kept the instructions...

Just kidding, Here we go. Photogenic fellas aint we!

Back to the shop, the knife is in the oven as we speak, and I'm startin in on the leather.

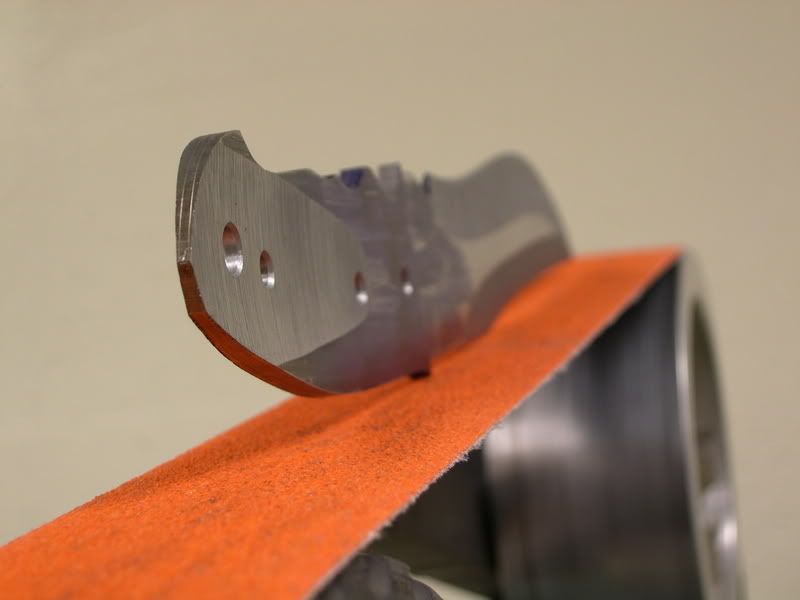

Started out this moring by milling my handle inserts.

Drilling the holes for the pins.

[img]

http://i123.photobucket.com/albums/o281 … CN1355.jpg[/img]

Daily time stamp.

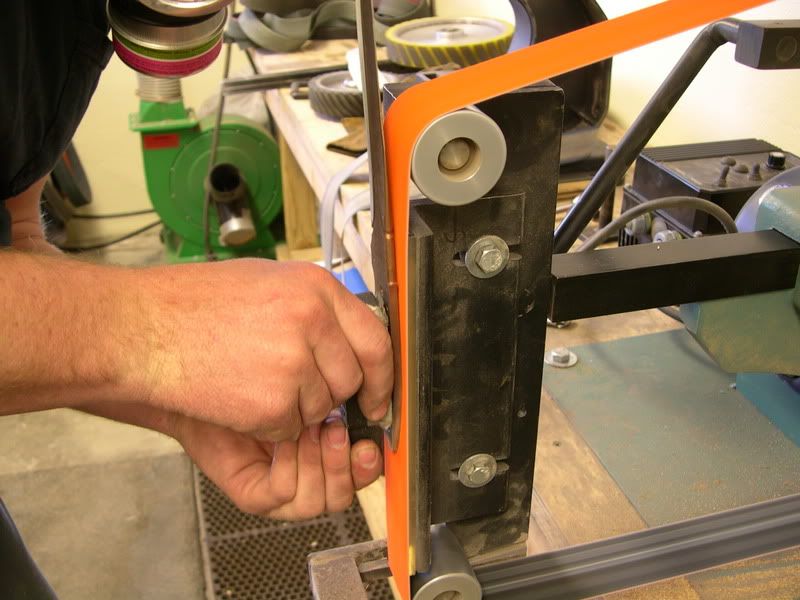

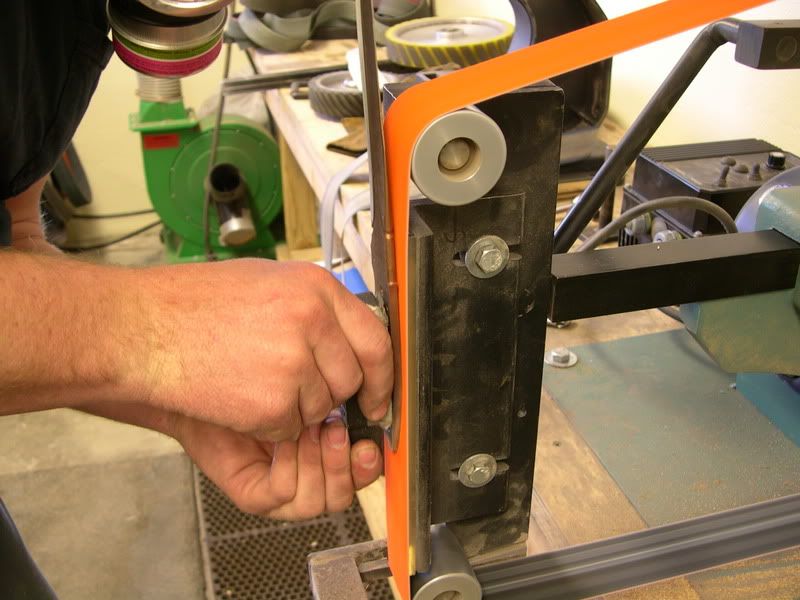

Tapering the tang, this was kind of tricky,

The finished tang,

Due to the tapered tang the scales needed a to have a beveled front edge of 1deg. It doesn't sound like much but it makes a big difference.

Drilling the scales,

Right in the middle of a hole I heard a "CLINK" in my drill press?

Took apart return spring housing and found that a piece of a spring had broken and jammed inside the downfeed …

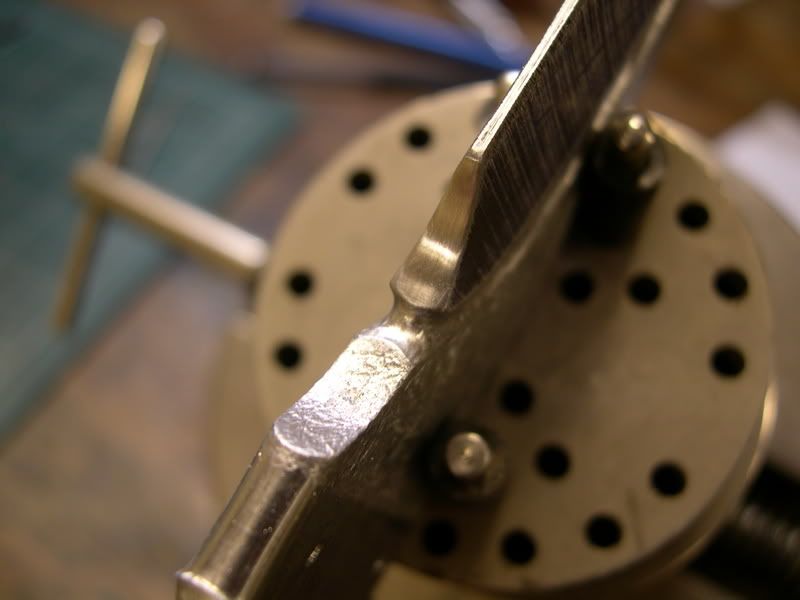

Heating a section of spring to re-bend the catch.

The temporarily repaired spring and the offending section.

Took me off the knife for about 30 minutes.

Got the rest of the holes drilled and started roughing out the scales.

I finally have all my handle pieces made..

I have to try and go find some Muriatic Acid for the etch, I'm hoping that I can get it at Home Depot, no one else has had it.

When I get back I'll finish grind the blade and start the assembly process